On the eve of the celebration of Gratitude Day, on February 27, 2026, a charity fair was held at the Faculty of History, Economics and Law, bringing t Read more

Quotation gallery

The long unmeasured pulse of time moves everything. There is nothing hidden that it cannot bring to light, nothing once known that may not become unknown.

Faculty News

On February 27, 2026, in anticipation of the «celebration of Gratitude Day», the Faculty of History, Economics, and Law hosted a warm gathering and a Read more

On February 27, 2026, the Faculty of History, Economics and Law held a career guidance meeting with students of the «Foundation» program and future ap Read more

24 февраля 2026 года на базе Северо-Казахстанский высший медицинский колледж имени Жұмағали Тлеулина КГУ «УЗ акимата СКО» прошла областная олимпиада п Read more

On February 19, 2026, students of the Faculty of History, Economics, and Law actively participated in the large-scale action «Nashakorlykka Zhol Zhok! Read more

On February 19, 2026, the Faculty of History, Economics, and Law held an explanation of the draft new Constitution of the Republic of Kazakhstan. The Read more

As part of the activities of the Kozybayev Alumni Association, a meeting was held at the Faculty of History, Economics, and Law, which became a signif Read more

17 февраля 2026 года в учебно-лабораторном корпусе (аудитория 636) состоялась литературно-музыкальная композиция «Бір шаңырақ астында» / «Под одним Read more

На базе медицинском факультете НАО «Северо-Казахстанский университет имени М. Козыбаева» состоялась дискуссионная площадка «Современная конституционна Read more

Students of the Faculty of History, Economics and Law, 3rd year of the educational program 6B04108 «Business and Management» (US), Zhanna Aleksandrovn Read more

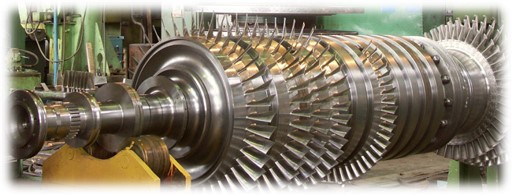

Development of metrological support and technological support for ultra-precise forecasting of failures of high-loaded equipment using non-destructive testing methods and integrated assessment of fatigue processes in the material of steam turbine blades a

Priority area: Information, telecommunication and space technologies, scientific research in the field of natural sciences

Project manager: Savinkin V.V., Doctor of Technical Sciences

Project executors: Demyanenko A.V., Candidate of Technical Sciences, Tadzhigitov A.A., Ph.D., Voronina O.A., Ph.D., Zhakupov M.A., Ph.D., Ratushnaya T.Yu., master, Ivanova O.V., master.

Terms of execution: 2018-2020

Amount of financing: 72,000,000 tenge.

Purpose of the project: Development of an innovative methodology for highly accurate prediction of structural and phase changes in a part and failures of highly loaded equipment.

Expected results: Improved quality of forecasting failures, process control, reduced likelihood of man-made disasters. Creation of an innovative methodology for ultra-precise forecasting.

Description of the project: The idea of the project is to study the concentration of internal stresses in the structure of dynamically loaded parts of turbines at the stage of pre-fracture, increasing the reliability and efficiency of their operation by ultra-precise forecasting. The technical solutions developed in the project will make it possible to predict with high accuracy the moment of pre-destruction and failure of highly loaded equipment, excluding man-made disasters at industrial enterprises in Kazakhstan. The synthesis of technical equipment and probabilistic methods will create a complete autonomous system for predicting defects at the structural level of a part without dismantling it, with the development of an intelligent control system and decision-making. An ultra-precise forecast will make it possible to adapt the optimal operating parameters and monitor the operation of the turbine. To conquer the market with a domestic information database that performs highly accurate forecasting.

Project objectives:

−application of proven methods and technologies for the development of metrological support and technological support for high-precision forecasting of failures of highly loaded equipment;

−analytical methods, methods of simulation modeling, development of normative and technical documentation for metrological support;

−use of non-destructive testing methods and integrated assessment of fatigue processes in the material of steam turbine blades at TPS.